A Journey Every Electronic Product Must Take

Imagine this.

You design a brilliant electronic product.

It works perfectly in your lab.

Your team celebrates.

The prototype is stable.

Performance looks excellent.

Then suddenly…

You cannot sell it.

Not in Europe.

Not in the US.

Not in India.

Not in aerospace.

Not in medical.

Why?

Because the product hasn’t completed its compliance journey.

🔌 The Invisible Gatekeepers of the Electronics World

Every electronic product — from a simple mobile charger to a life-saving medical device — must pass through invisible gates before entering the global market.

These gates are called:

- Certifications

- Standards

- Regulatory approvals

- Compliance requirements

They are not just paperwork.

They are the world’s safety language.

They ensure:

- ⚡ You don’t get electric shock

- 🔥 Your device doesn’t catch fire

- 📡 It doesn’t disturb nearby electronics

- 🏥 It doesn’t risk patient life

- 🚗 It survives automotive conditions

- ✈️ It performs reliably in aircraft

- 🚢 It resists harsh marine environments

Compliance is not bureaucracy.

It is engineered trust.

🌎 One Product. Many Worlds.

An electronic product may enter different worlds:

- 🏠 Consumer electronics

- 🚗 Automotive

- 🏭 Industrial

- 🏥 Medical

- ✈️ Aerospace

- 🛡 Defence

- 🚢 Naval / Marine

Each world has its own expectations.

Its own standards.

Its own certification process.

A consumer device might follow IEC safety and EMC standards.

An automotive ECU must survive load dumps and transients.

A medical device must protect human life under single-fault conditions.

A defence product must survive extreme environmental abuse.

Same electronics.

Different compliance universe.

🧠 Why Engineers Must Understand Compliance

Many engineers think compliance is something that happens after design.

In reality:

Compliance starts on Day 1 of design.

If ignored early:

- Redesign costs multiply

- Launch timelines slip

- Certification failures happen

- Reputation suffers

But when understood deeply:

- Design becomes robust

- Time-to-market reduces

- Global market access becomes smoother

- Engineering maturity increases

Compliance thinking transforms engineers into system architects.

🚀 This Is Just the Beginning

This article is only an introduction.

In the upcoming series, we will build a complete learning roadmap:

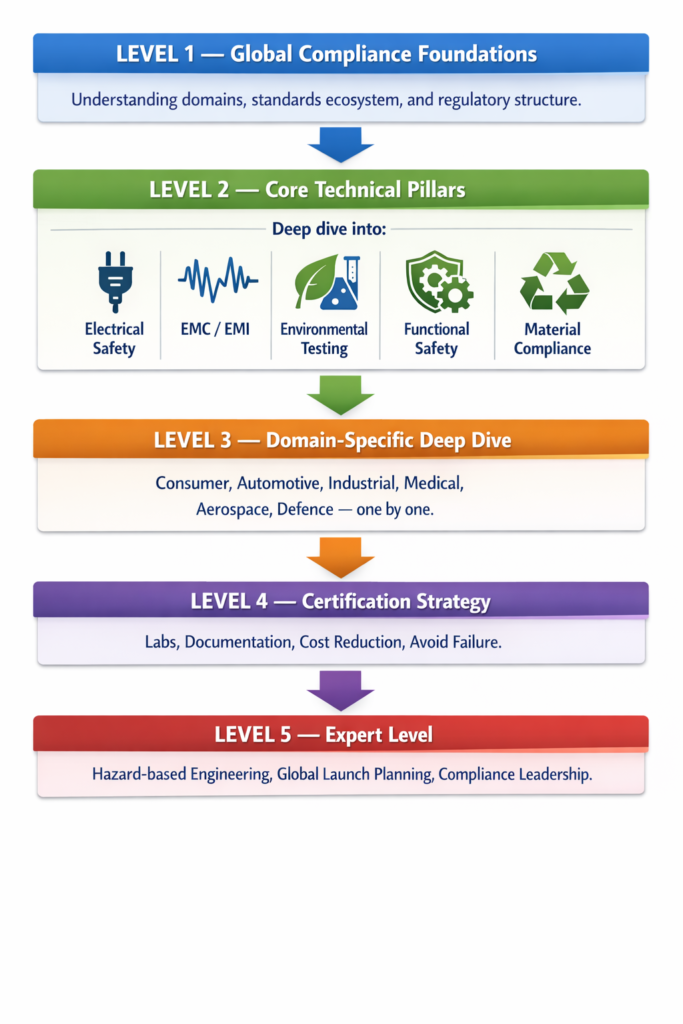

LEVEL 1 — Global Compliance Foundations

Understanding domains, standards ecosystem, and regulatory structure.

LEVEL 2 — Core Technical Pillars

Deep dive into:

- Electrical Safety

- EMC / EMI

- Environmental testing

- Functional safety

- Material compliance

LEVEL 3 — Domain-Specific Deep Dive

Consumer, Automotive, Industrial, Medical, Aerospace, Defence, Marine — one by one.

LEVEL 4 — Certification Strategy

How to interact with labs, prepare documentation, reduce cost, avoid failure.

LEVEL 5 — Expert Level

Hazard-based engineering thinking, global launch planning, compliance leadership.

By the end of this journey, you won’t just know certifications.

You will understand:

- Why they exist

- How they shape product design

- How to engineer with compliance in mind

- How to build globally accepted products

🎯 If You Design Electronics, This Journey Is for You

Whether you are:

- A young electronics engineer

- A design lead

- A compliance engineer

- An entrepreneur

- Or building an ODM ecosystem

Understanding compliance is not optional.

It is the backbone of global engineering.

🔥 Ready to Go Deeper?

In the next article, we begin with:

LEVEL 2 — Electrical Safety Foundations

The science behind shock protection, insulation, fire prevention, and hazard-based engineering.

This is where real engineering thinking begins.

Stay curious.

Stay compliant.

Stay ahead.

Let’s build globally trusted electronics — step by step.

Leave a Reply